bag cement feeding system

Normally, we use bulk cement tanker to deliver cement to the concrete batching plant. On the bulk cement tanker, there is a air blower to deliver cement into cement silo.

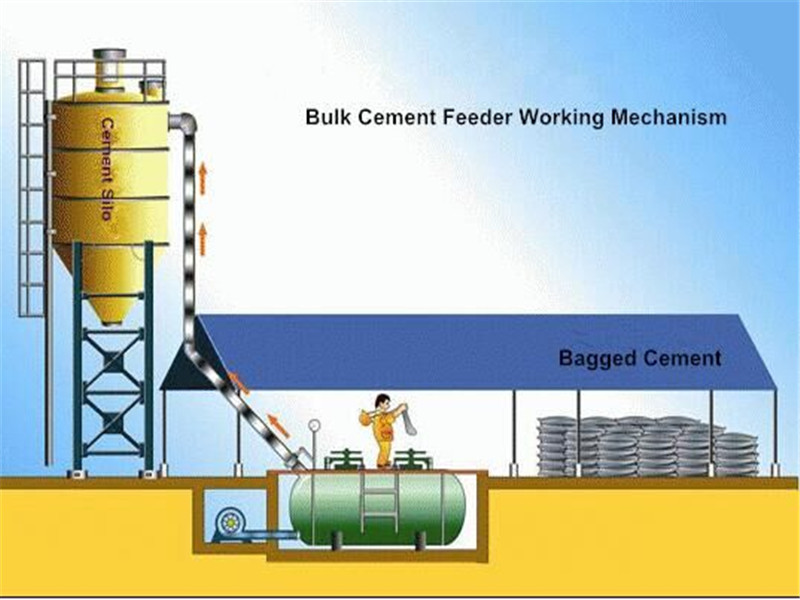

But sometimes our customers need to use bag type cement. For example, the concrete batching plant is located on small island, there is no bulk cement supply. In order to meet the requirements of our customers, we developed the bag cement feeding system.

There are two types of bag cement feeding system:

1. Without cement silo type. There will be no cement silo, the cement will be delivered to cement scale directly;

2. With cement silo type. There will be cement silo, cement will be delivered to cement silo first and then delivered to cement scale.

1. Without cement silo type of bag cement feeding system:

1) It is composed of a cement hopper and a screw conveyor;

2) work procedure: workers manually put cement bag into the cement hopper; the knives inside the hopper will break the cement bag and cement will be discharged into the hopper; the screw conveyor will deliver cement to cement scale on top of concrete mixer;

3) Features of this type of bag cement feeding system: cost-saving, easy to install, but there will be much dust discharged into the air;

2. With cement silo type of bag cement feeding system. This type of bag cement feeding system can be devided into two types as well:

1) automatic type

A. It is composed of belt conveyor, cement bag breaker, screw conveyor and pneumatic cement feeder;

B. Work procedure: belt conveyor delivers cement bag to bag breaker, bag breaker breaks cement bag and cement will be discharged into bag breaker, screw conveyor delivers cement to pneumatic cement feeder which will deliver cement to cement silo;

C. Features of this type of bag cement feeding system: high efficiency and environment friendly, but very big bag cement can not be processed.

评论

发表评论